Comparing HDPE Liners and Epoxy

for Concrete Safety in Florida

Protecting concrete structures in Florida is no simple task. With high humidity, frequent rain, and the harsh effects of saltwater in coastal areas, concrete face numerous challenges that can compromise its integrity. Finding the right solution to keep concrete safe and long-lasting involves comparing different protection methods, like HDPE liners and epoxy coatings.

HDPE concrete liners and epoxy coatings are both popular choices for shielding concrete, but they work in different ways and offer unique benefits. HDPE liners, made from high-density polyethylene, create a waterproof barrier that adheres flexibly to the concrete surface. On the other hand, epoxy coatings form a hard, chemical-resistant layer when applied.

By understanding these factors, you can make an informed decision on the best option for protecting your concrete structures in Florida, whether it be Jacksonville, Tampa, Orlando, St. Petersburg or smaller centers.

Understanding HDPE Liners and Epoxy Coatings: An Overview

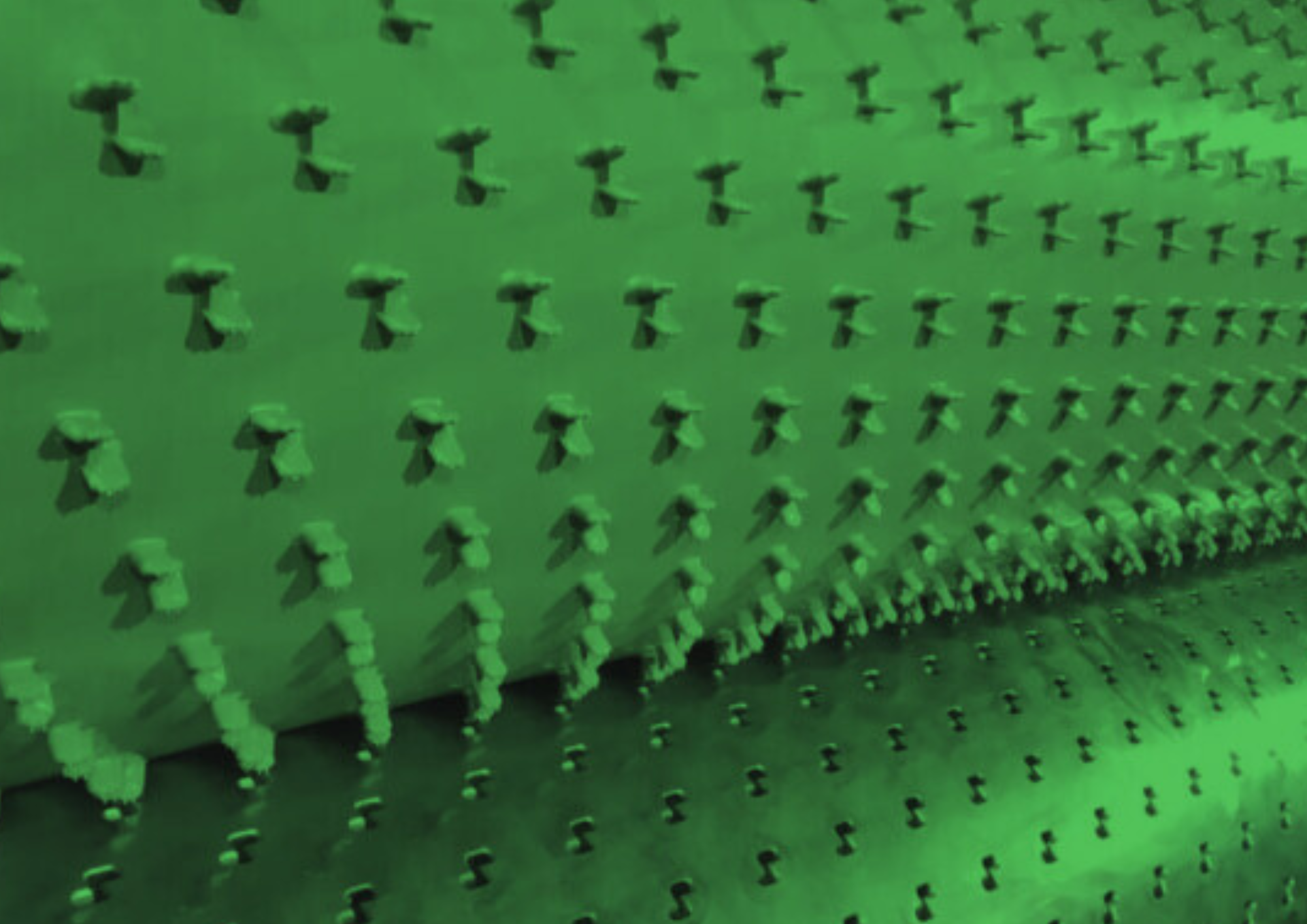

HDPE liners and epoxy coatings serve as effective solutions for concrete protection, each with its own methodologies and benefits. HDPE, which stands for High-Density Polyethylene, is a type of plastic renowned for its robustness and flexibility. These liners are designed to form a seamless and waterproof barrier over concrete surfaces, making them highly suitable for environments where moisture and chemical resistance are critical.

On the other hand, epoxy coatings are created by mixing a resin with a hardener, forming a rigid and durable layer when applied to concrete. Epoxy coatings are known for their strong adhesive properties and high resistance to chemicals, making them a common choice for industrial settings. However, their lack of flexibility can be a downside in areas with structural movement or varying environmental conditions.

When comparing the two, HDPE liners typically offer greater flexibility and durability in the face of environmental stresses, while epoxy coatings deliver a tough, chemical-resistant surface. The choice between HDPE liners and epoxy coatings hinges on factors like specific environmental conditions and the desired longevity of the protection.

Environmental Resistance: How Each Coating Holds Up in Florida's Climate

Florida's climate poses significant challenges to concrete structures due to its high humidity, frequent rain, and proximity to saltwater. HDPE liners excel in these conditions primarily because of their excellent moisture resistance. These liners prevent water from penetrating the concrete, thus averting issues like rusting of reinforcements and concrete spalling. The flexibility of HDPE liners also means they can expand and contract with changing temperatures, preventing cracks and other damage.

Conversely, while epoxy coatings are highly resistant to a range of chemicals, their strength can become a weakness in Miami's fluctuating environment. The rigid nature of epoxy makes it less adaptable to thermal expansion and contraction, increasing the likelihood of cracks developing over time. Additionally, once damaged, epoxy coatings are challenging to repair without fully reapplying the layer.

Saltwater is another factor that cannot be ignored in Florida. HDPE liners provide a robust defense against saltwater intrusion, protecting the underlying concrete and steel reinforcements from corrosion. Epoxy, while capable of resisting chemical corrosion, can suffer from its rigidity and potentially let in saltwater if any cracks occur.

HDPE concrete liners offer superior environmental resistance for the specific challenges posed by Florida's climate, making them a reliable choice for long-term concrete protection.

Installation and Maintenance: Time, Cost, and Complexity

When looking at installation and maintenance, HDPE liners and epoxy coatings present very different scenarios. HDPE liners are relatively straightforward to install. They are typically applied in sheets that are heat (extrusion) welded after being imbedded into the concrete surface. This process, while requiring skill and precision, tends to be less labour-intensive and time-consuming than epoxy applications. HDPE liners also have fewer preparation requirements, as it happens at the time of the concrete pour - whether in the precast production facility or in situ.

Epoxy coatings, on the other hand, require extensive surface preparation. The concrete must be thoroughly cleaned and prepped, often needing a primer coat to ensure proper adhesion. The application itself involves mixing precise ratios of resin and hardener, applying it in layers, and then waiting for it to cure. This process can take several days, during which the area must remain undisturbed. Furthermore, any mistakes in application can compromise the integrity of the coating, necessitating costly rework.

Maintaining HDPE concrete liners is generally easier as well. Since they are resilient and flexible, they require minimal upkeep. If damage does occur, repairs can often be made quickly by patching or welding a new section of liner over the damaged area. Epoxy coatings, in contrast, are harder to patch and repair, often needing partial or complete reapplication to ensure the integrity of the protective layer. This makes HDPE liners more straightforward to install and cost-effective to maintain in the long run.

Long-Term Performance and Cost Efficiency

In terms of long-term performance, HDPE liners offer significant advantages over epoxy coatings, especially in environments like Orlando, Tampa or Florida in general. HDPE liners are known for their durability and ability to withstand various environmental stressors. Their flexibility ensures they remain intact even as concrete structures expand and contract due to temperature changes or shifting ground conditions. This flexibility translates into fewer cracks and breaks, meaning the protection they offer remains uninterrupted over time.

Epoxy coatings, while durable, can become brittle over time, particularly when exposed to Florida’s intense sunlight and fluctuating temperatures. Once cracks develop in an epoxy coating, its protective qualities are compromised, and repairs can be challenging and costly. The need for frequent inspections and potential reapplications adds to the expense, making epoxy coatings less cost-efficient in the long term.

The long-term savings in maintenance, repairs, and replacements make HDPE Concrete Protection Liners a better investment. HDPE liners have a longer lifespan and fewer maintenance needs, which can significantly reduce the total cost of ownership. This is crucial for large-scale projects where the longevity and reliability of the protective coating can impact the overall budget and timeline.

HDPE liners prove to be more cost-efficient and reliable over time, offering a better return on investment by minimizing ongoing maintenance and extending the lifespan of concrete structures.

Miami, Florida

United States of America

In Florida protecting concrete structures from the detrimental effects of humidity, rain, and saltwater is a challenging task. By comparing HDPE liners and epoxy coatings, we can see that HDPE liners offer superior advantages in terms of flexibility, durability, and long-term cost efficiency. Their ability to withstand the harsh climate conditions without cracking or deteriorating makes them an excellent choice for ensuring the longevity and safety of concrete structures.

If you’re looking to maximize the lifespan and performance of your concrete investments throughout Florida, HDPE liners are a clear winner. Their robust environmental resistance and ease of maintenance provide peace of mind and significant cost savings over time. For tailored solutions and professional guidance on the best geomembrane containment liner for your project, contact Engineered Containment. Together, we can protect and sustain your concrete structures for years to come.