HDPE Liners for Southern California Concrete

Southern California poses several challenges for maintaining the integrity of concrete structures. The region's climate consists of hot, dry summers and cooler, damp winters. These extreme temperature shifts cause concrete to expand and contract, leading to cracks and long-term damage. Protecting concrete from these environmental stressors is crucial to extend its lifespan and ensure structural safety.

Understanding the Unique Challenges of Concrete in Southern California

Concrete structures in Southern California face a range of environmental challenges that can impact their longevity and performance. One of the biggest issues is the region’s temperature variations. Hot, dry summers cause concrete to expand, while cooler, moist winters make it contract. This constant shifting creates stress within the concrete, leading to cracks and other forms of deterioration over time.

Coastal areas add another layer of complexity with their salty air. Salt is highly corrosive and, when it penetrates concrete, it reaches the steel reinforcements inside. This leads to rust and corrosion, which weaken the structure from within. Buildings, bridges, and roads near the coast are particularly vulnerable to this kind of damage, necessitating more robust protective measures to maintain their integrity.

Lastly, Southern California is known for its seismic activity. The region experiences frequent earthquakes, which can worsen existing cracks or create new ones in concrete structures. Even minor tremors put additional stress on these materials, increasing the risk of significant damage. Given these challenges, effective concrete protection solutions are essential for ensuring long-term durability and safety.

Key Advantages of HDPE Liners Over Other Solutions

HDPE (high-density polyethylene) liners offer multiple advantages that make them a superior choice for concrete protection, especially in areas like Southern California. These benefits are clear when compared to other conventional solutions like epoxy coatings.

Flexibility: HDPE liners are incredibly flexible, which allows them to adapt to the expansion and contraction of concrete. This flexibility prevents the formation of cracks and splits, maintaining the structural integrity of the concrete over time.

Chemical Resistance: Unlike epoxy coatings, which can degrade over time, HDPE liners resist a wide range of chemicals, including the salts found in coastal air. This helps protect the steel reinforcements inside the concrete from corrosion, ensuring a longer lifespan for the structure.

Durability: When it comes to surviving extreme environmental conditions, HDPE liners stand out. They are designed to be durable and long-lasting, providing consistent protection without the need for frequent replacements or repairs. This durability makes them a cost-effective option when considering long-term maintenance.

Ease of Installation: Installing HDPE liners is generally faster and easier compared to other solutions. They can be pre-fabricated to fit specific shapes and sizes, which simplifies the installation process and reduces labour costs. This efficiency means that projects can be completed quicker, minimizing disruptions.

Low Maintenance: Once installed, HDPE liners require minimal maintenance to remain effective. This is a stark contrast to epoxy coatings, which often need regular upkeep to maintain their protective qualities. The low maintenance requirement further contributes to the overall cost savings associated with HDPE liners.

These advantages highlight why HDPE liners are an excellent choice for concrete protection in Southern California. They offer the flexibility, chemical resistance, and durability needed to withstand the region’s unique challenges, making them a wise investment for any concrete structure.

How HDPE Liners Enhance Durability and Reduce Maintenance

One of the standout features of HDPE liners is their exceptional durability. These liners are made to withstand harsh environmental conditions, making them perfect for Southern California's diverse climate. Unlike epoxy coatings, which can wear down over time, HDPE liners remain intact for many years. This longevity reduces the frequency of repairs and replacements, saving both time and money.

HDPE liners also require minimal maintenance once installed. Their robust construction means they are resistant to damage from chemicals, salts, and other corrosive materials. This resistance ensures that the concrete remains protected, and the need for ongoing maintenance is significantly reduced. The low maintenance requirements make HDPE liners a cost-effective solution for long-term concrete protection.

Another benefit is their ease of inspection. HDPE liners allow for easier and quicker inspections compared to other methods. This ease of inspection is crucial for identifying and addressing potential issues before they escalate into major problems. By enhancing durability and reducing maintenance needs, HDPE liners offer a reliable and efficient way to protect concrete structures in Southern California.

Practical Applications of HDPE Liners in Southern California

HDPE liners are versatile and can be used in various applications to protect concrete structures in Southern California. Here are some practical uses:

Water Retention Systems: HDPE liners are commonly used in water containment systems like reservoirs, ponds, and canals. Their ability to prevent leaks and withstand chemical exposure makes them ideal for these applications.

Industrial Facilities: Industrial plants often deal with hazardous chemicals that can damage concrete. HDPE liners provide an effective barrier, protecting the concrete and ensuring the safe operation of these facilities.

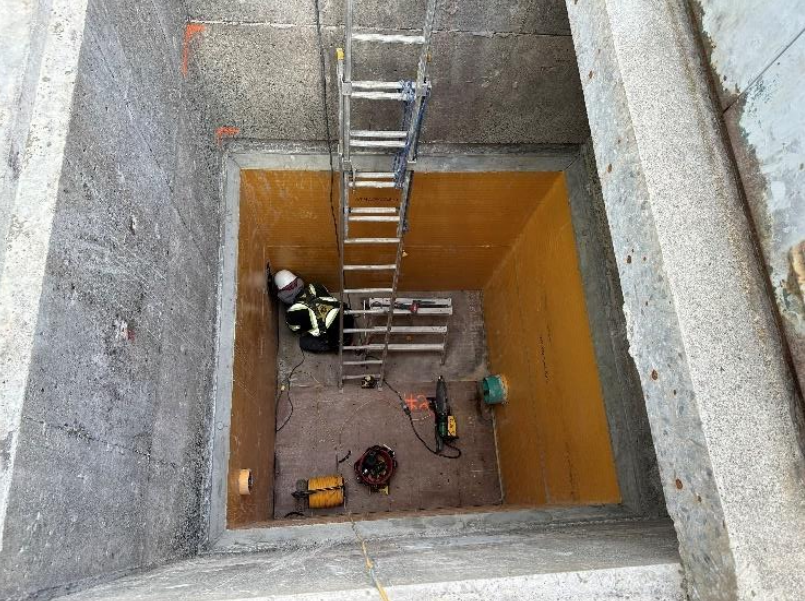

Wastewater Treatment Plants: These plants need to handle various contaminants that can corrode concrete. HDPE liners offer a durable solution that minimizes the risk of damage and extends the service life of the treatment tanks and other containment structures.

Coastal Structures: Buildings and infrastructure near the coast are exposed to salty air and spray, which can accelerate corrosion. HDPE liners are an excellent choice for protecting these structures from the harsh marine environment.

Why Concrete Protective Liner?

Protecting concrete structures in Southern California presents unique challenges due to the region's diverse climate and environmental factors. HDPE liners offer a superior solution by enhancing durability, reducing maintenance needs, and providing a cost-effective method for long-term protection. Their versatility makes them suitable for a wide range of applications, from water retention systems to coastal structures.

Investing in HDPE liners helps ensure the longevity and safety of concrete structures, making them a smart choice for any project. If you're looking to protect your concrete investments in Southern California, consider the many benefits HDPE liners offer.

Contact Engineered Containment today to learn more about how our HDPE liners can meet your concrete protection needs. Our team is ready to help you explore the best solutions for your specific requirements.

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!