HDPE Liners vs. Epoxy: Best Concrete Protection in Ontario

Ontario’s Premier Source of Concrete Protective Liner

Material Supply | Design Support | Installation & Installation Support | QA/AC | Inspections

The team at Engineered Containment has been proudly serving the North American market, including Ontario, with environmental protection measures, including concrete protective liner for nearly 2 decades!

Maintaining the integrity of concrete is crucial for various industries in Toronto, Ottawa, and their surrounding regions. From wastewater treatment plants to chemical storage facilities, concrete structures face numerous challenges that can lead to damage and deterioration over time. One significant factor is Ontario's climate, which can be harsh and unpredictable. The freeze-thaw cycles in winter and the humid summers can cause concrete to crack and weaken, making effective protection methods essential.

In the realm of concrete protection, two primary methods are often discussed: HDPE liners and epoxy coatings. While both serve to shield concrete from damage, HDPE liners have distinct advantages that make them a better choice for many applications. HDPE liners are crafted from a durable plastic that provides excellent chemical resistance and flexibility, making them ideal for robust industrial settings. Conversely, epoxy coatings offer a hard, smooth finish but can be prone to cracking and require meticulous application processes.

It is critical to understand the challenges of protecting concrete in Ontario’s unique climate, the advantages of HDPE liners over epoxy coatings, real-world applications where HDPE liners excel, and the long-term benefits for industries in Ontario. By understanding these factors, you can make an informed decision about the best method to protect your concrete structures.

130 King Street West

Suite 1900

Toronto, Ontario Canada

M5X 1E3

The Challenges of Protecting Concrete in Ontario’s Climate

Concrete protection in Ontario presents unique challenges due to the region’s climate. The frequent freeze-thaw cycles during winter cause concrete to expand and contract. This repeated stress can lead to cracks and spalling, compromising the structural integrity. When water seeps into these cracks and freezes, it expands, worsening the damage over time. Ensuring concrete remains intact through extreme temperature variations is essential for the safety and functionality of industrial facilities.

During the warmer months, Ontario's high humidity can contribute to the deterioration of concrete. Moisture promotes the growth of mould and mildew, leading to surface decay and creating a hazardous environment. Additionally, industrial activities often involve chemicals that, if not contained, can quickly degrade exposed concrete. Without proper protection, these factors can necessitate frequent repairs, costing time and resources.

Moreover, salting roads and pathways to manage ice in the winter introduces another layer of challenge. Salt can penetrate the concrete, causing internal damage and leading to further deterioration. Protecting concrete effectively requires a solution that can withstand chemical exposure, resist moisture infiltration, and accommodate the natural movements caused by temperature changes. This is where HDPE liners provide a significant advantage over other methods, such as epoxy coatings.

Advantages of HDPE Liners Over Epoxy Coatings

HDPE liners offer several distinct advantages over epoxy coatings, making them a superior choice for concrete protection in Ontario. First and foremost, HDPE liners are extremely flexible. This flexibility allows them to accommodate the natural movements of concrete caused by freeze-thaw cycles, effectively preventing cracks and spalling. Unlike epoxy coatings, which can become brittle and crack under stress, HDPE liners maintain their integrity, providing long-lasting protection.

Chemical resistance is another area where HDPE liners excel. In industrial settings where exposure to harsh chemicals is common, HDPE liners provide a robust barrier that prevents these substances from penetrating the concrete. Epoxy coatings, while durable, may not offer the same level of resistance against a wide range of chemicals. Over time, this can lead to degradation and the need for frequent maintenance or replacement of the epoxy coating.

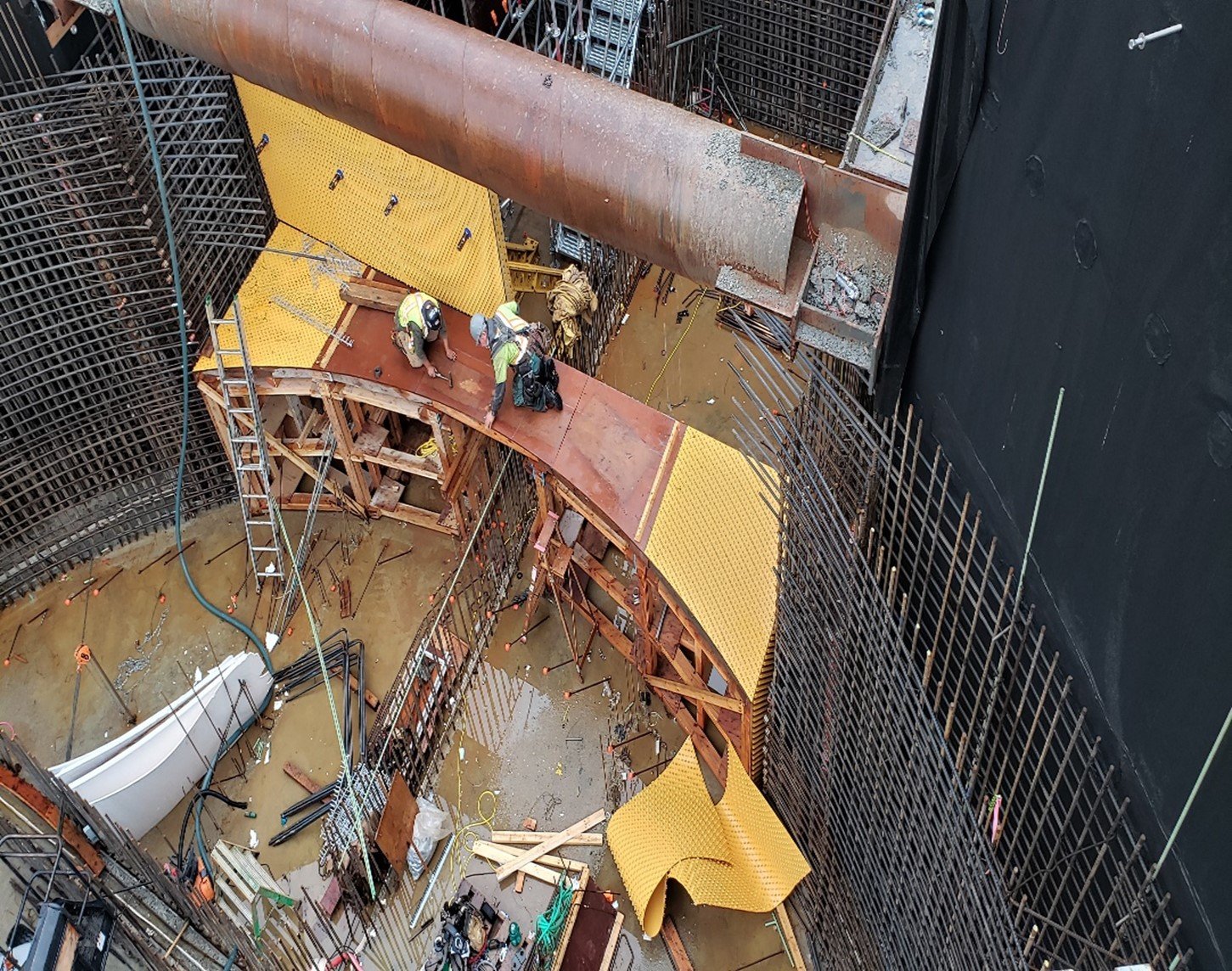

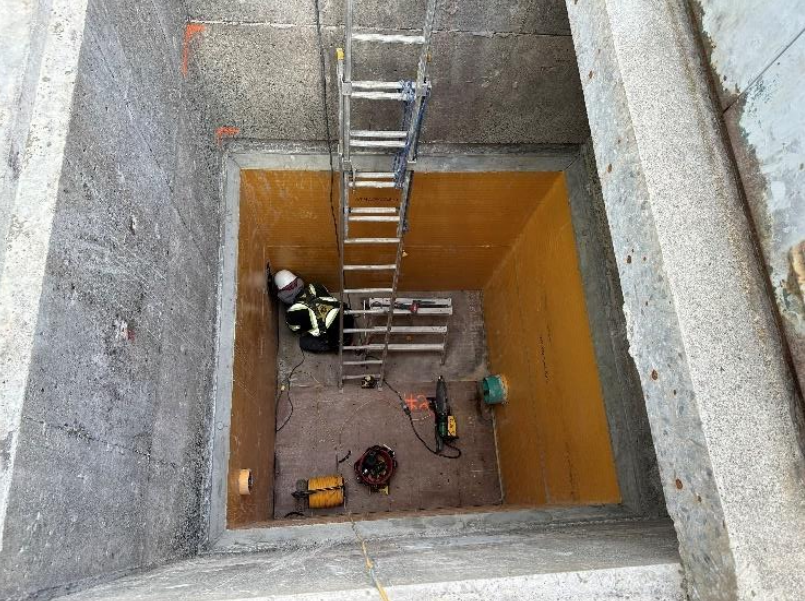

HDPE liners are also easier and quicker to install compared to epoxy coatings. Epoxy requires a meticulously clean and dry surface and can take several days to cure properly. Any mistakes during application can result in adhesion problems, leading to bubbles or peeling. In contrast, HDPE liners are cast directly into the concrete surface either at the precast producer’s facility (Lafarge, Heidelberg, Decast, etc.) or cast in place on-site. This installation efficiency translates to reduced downtime and lower overall costs for industrial operations.

Real-World Applications Where HDPE Liners Excel

HDPE liners are versatile and excel in various real-world applications, providing concrete protection that meets the demands of diverse industrial environments in Ontario. One primary application is within wastewater treatment plants. Here, concrete tanks and basins are constantly exposed to corrosive chemicals, moisture, and varying temperatures. HDPE liners ensure these structures remain intact, preventing leaks and maintaining the integrity of the plant’s operations efficiently.

HDPE liners are also a top choice for chemical storage facilities. These facilities handle a variety of hazardous materials that can significantly degrade concrete over time. HDPE liners offer exceptional chemical resistance, providing a formidable barrier that safeguards the concrete and the environment. This protection helps facilities comply with regulations and prevents costly environmental contamination.

Another important application area is in mining operations. The abrasive and chemical-laden environment of mining sites can quickly erode unprotected concrete. HDPE liners withstand the harsh conditions found in these sites, extending the life of containment systems used to store mining by-products and reducing maintenance needs.

Long-Term Benefits of HDPE Liners for Ontario Industries

When considering long-term benefits, HDPE liners offer several advantages that make them the preferred choice for concrete protection in Ontario industries. One major benefit is increased durability. HDPE liners are designed to last for decades, reducing the need for frequent replacements and repairs. This long lifespan translates to significant cost savings over time, allowing industries to allocate resources to other critical areas.

HDPE liners also contribute to environmental sustainability. They are made from recyclable materials, which helps reduce waste. Their resistance to chemicals and moisture minimizes the risk of environmental contamination, aligning with eco-friendly initiatives and compliance requirements in Ontario.

Additionally, the straightforward installation and maintenance of HDPE liners lead to reduced downtime for industrial operations. Quick and efficient installation processes mean that facilities can resume their operations sooner, minimizing disruptions. With minimal maintenance required, HDPE liners ensure continuous and reliable protection for critical infrastructure, enhancing operational efficiency and safety.

Understanding the unique challenges of protecting concrete in Ontario’s climate and the specific advantages of HDPE liners over epoxy coatings is essential for industrial decision-makers. HDPE liners offer unparalleled flexibility, chemical resistance, and ease of installation, making them the superior choice for concrete protection in various industrial applications.

For industries in Toronto and surrounding regions (The Region of Peel,etc.), the long-term benefits of HDPE liners are clear. From wastewater treatment plants to chemical storage facilities and mining operations, HDPE liners provide durable, efficient, and environmentally friendly solutions. These liners ensure the longevity and integrity of concrete structures, delivering cost-effective protection that withstands Ontario’s demanding climate and industrial conditions.

If you're looking for reliable and durable concrete protection solutions such as AGRU Ultragrip or Solmax (formerly GSE) Studliner, Engineered Containment is here to help. Our expertise in HDPE liners ensures that your infrastructure remains secure and efficient. Contact Engineered Containment today to learn more about how we can provide the perfect protection for your industrial needs.