HDPE Liners vs Epoxy:

Best Protection for Miami Concrete

Concrete structures in Miami face numerous challenges due to the city's unique climate and environmental conditions. High humidity, frequent rain, and proximity to saltwater create a harsh environment for concrete. This makes it essential to choose an effective protection method to ensure the longevity of these structures. Two popular options for concrete protection are HDPE liners and epoxy coatings, each with its own set of advantages and drawbacks.

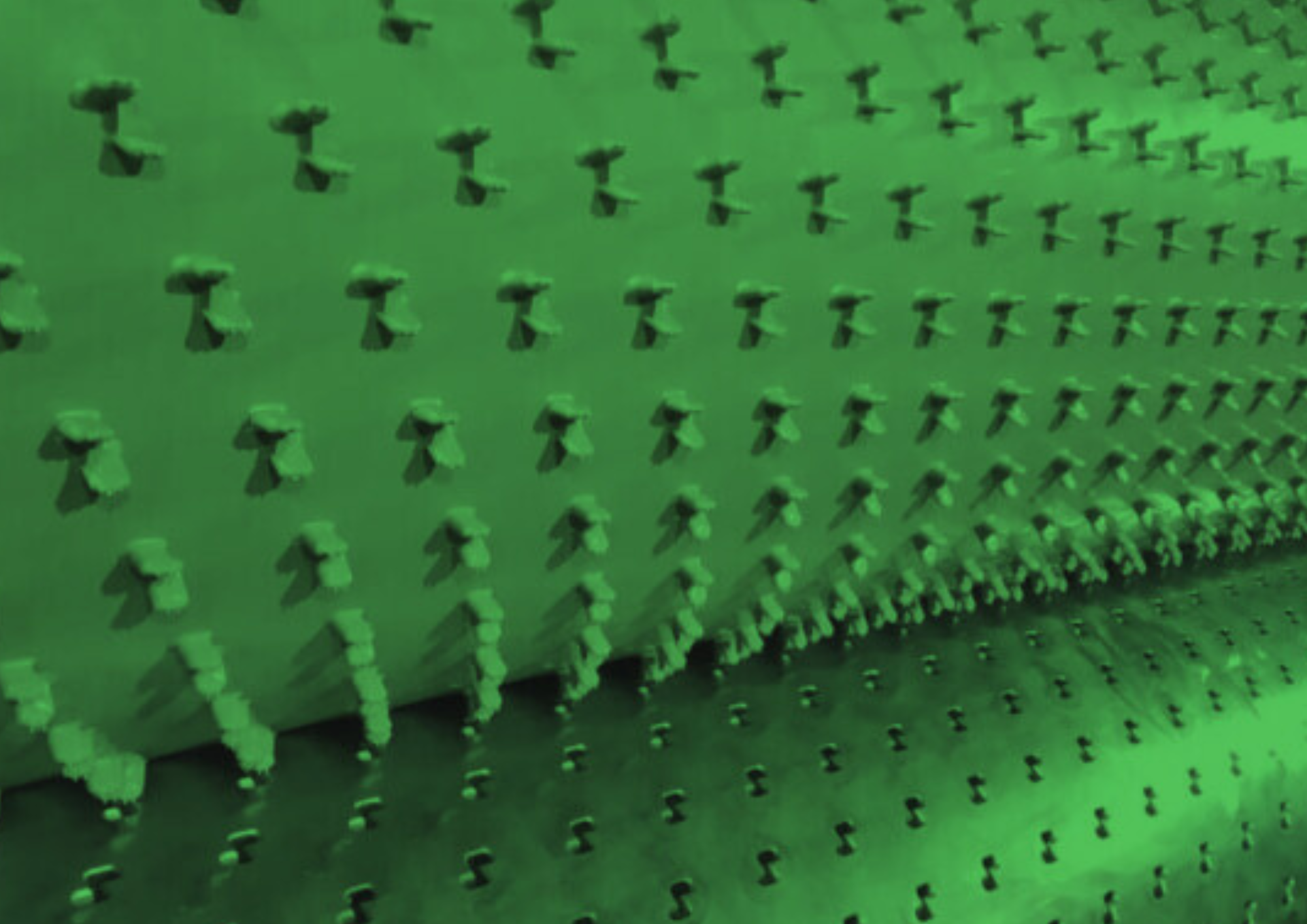

HDPE liners, made from high-density polyethylene, are known for their flexibility and excellent moisture resistance. These liners create a seamless, impervious barrier that adapts well to the concrete surface, making them highly effective in shielding against water and chemical exposure. They are particularly useful in preventing the ingress of contaminants that can weaken the concrete over time.

Epoxy coatings, in contrast, form a hard, durable layer when applied to concrete. Known for their strong adhesion and resistance to chemicals, epoxies are often used in industrial and commercial settings. However, their rigidity can become a disadvantage under certain conditions, especially in environments that experience significant temperature changes or structural stress.

Moisture and Water Resistance

Protecting concrete structures from moisture and water is critical, especially in a city like Miami, where high humidity and frequent rain are common. HDPE liners excel in providing moisture resistance due to their impermeable nature. Made from high-density polyethylene, these liners create a seamless barrier that prevents water from penetrating the concrete surface. This helps in avoiding problems like concrete spalling and corrosion of the reinforcing steel bars.

Epoxy coatings, while also offering a measure of water resistance, do not perform as well as HDPE liners in environments with constant moisture. Epoxy forms a rigid, hard layer on the concrete, which can crack under stress or temperature changes. These cracks can allow water to seep through, compromising the integrity of the concrete. Over time, even small cracks can lead to significant moisture damage, requiring costly repairs and maintenance to address the issue.

HDPE liners, on the other hand, are designed to withstand such stresses without compromising their sealing capabilities. Their flexibility ensures that even if the concrete expands or contracts due to temperature fluctuations, the liner maintains its impermeable barrier. This makes HDPE liners a superior choice for keeping concrete structures protected from moisture and water intrusion in Miami's challenging climate.

Chemical and Saltwater Protection

Concrete structures in Miami are not only exposed to high levels of moisture but also to chemicals and saltwater, especially in coastal areas. These elements can be particularly damaging, leading to chemical reactions that weaken the concrete. HDPE liners offer robust protection against chemical and saltwater exposure due to their chemical-resistant properties.

The high-density polyethylene material used in HDPE liners is resistant to a wide range of chemicals, including acids, bases, and salts. This makes them ideal for environments where the concrete might come into contact with harmful substances. The seamless and continuous barrier provided by an HDPE liner prevents these chemicals from reaching the concrete, thereby preserving its structural integrity and prolonging its lifespan.

Epoxy coatings are also known for their chemical resistance, but they fall short when compared to HDPE liners in terms of long-term durability and flexibility. While an epoxy-coated surface can resist chemical spills initially, any damage or cracking can create pathways for chemicals to penetrate the concrete. Repairing these cracks can be both difficult and expensive, reducing the overall effectiveness of the protection.

HDPE liners offer superior chemical and saltwater protection for concrete structures in Miami. Their ability to withstand a broad range of chemicals and corrosive elements makes them the better choice for ensuring long-lasting and reliable concrete protection in harsh environments.

Flexibility and Durability in Extreme Weather

Miami’s weather can be extreme, with intense sun, heavy rains, and occasional hurricanes. These conditions demand flexible and durable protection for concrete structures. HDPE liners stand out due to their exceptional flexibility and ability to withstand these stresses without compromising their protective properties. Made from high-density polyethylene, these liners can expand and contract with temperature changes, preventing the formation of cracks and ensuring continuous protection.

Epoxy coatings, while providing a hard protective layer, lack the flexibility needed to adapt to such extreme weather. Their rigid nature makes them prone to cracking under temperature fluctuations or structural movement. Once cracks form, water, chemicals, and other contaminants can easily penetrate, leading to potential damage to the concrete.

Furthermore, HDPE liners are designed to resist UV radiation, which is essential in Miami’s sunny climate. Prolonged exposure to sunlight can degrade many materials, but HDPE retains its integrity, providing long-lasting protection. This makes HDPE liners a more durable and reliable option for safeguarding concrete structures against Miami’s varied and harsh weather conditions.

Cost-Effectiveness and Maintenance Requirements

When it comes to cost-effectiveness and maintenance, HDPE liners offer significant advantages over epoxy coatings. While the initial installation cost of HDPE liners may be higher, their long-term benefits and lower maintenance costs make them a more economical choice. HDPE liners are durable and require minimal maintenance, reducing the need for frequent repairs or replacements.

On the other hand, epoxy coatings can be less expensive to apply initially, but their long-term maintenance costs can add up. Their tendency to crack under stress means that repairs can be frequent and costly. Additionally, if the epoxy coating needs to be replaced, it often requires removing the old layer, which can be time-consuming and expensive.

HDPE liners, due to their superior flexibility and durability, do not require such extensive maintenance. This makes them not only more cost-effective over time but also more reliable in providing consistent protection for concrete structures. When evaluating the total cost of ownership, HDPE liners clearly emerge as the more financially sound solution for concrete protection in Miami.

Miami, Florida

United States of America

Protecting concrete structures in Miami necessitates choosing materials that can withstand the city’s harsh environmental conditions. HDPE liners have proven to be more effective than epoxy coatings in many critical areas. Their superior moisture and water resistance, robust chemical and saltwater protection, and exceptional flexibility make them the best choice for ensuring the longevity and integrity of concrete structures.

Epoxy coatings, while offering some benefits, fall short in key areas such as flexibility and long-term durability. Their susceptibility to cracking and frequent maintenance needs make them less ideal for Miami’s extreme weather and environmental challenges.

For any project in Miami that requires reliable and long-lasting concrete protection, consider using HDPE liners. Their initial cost is offset by their reduced maintenance needs and extended lifespan, making them a more economical and effective solution. If you’re ready to upgrade your concrete protection, Contact Engineered Containment to learn more about how our HDPE liners can safeguard your structures for years to come.