Concrete Protection in Southern California

HDPE Liners vs. Epoxy

Concrete structures in Southern California face unique challenges due to the region’s environment and seismic activity. Hot, dry summers, followed by cool, wet winters, cause concrete to expand and contract, leading to cracks and weakening over time. Coastal areas experience the additional issue of salt air, which speeds up the corrosion process. These conditions make it essential to find a reliable and durable method for concrete protection. One common method for protecting concrete is using epoxy coatings. While epoxy has its benefits, there is another option worth considering: HDPE liners. HDPE, or high-density polyethene, offers superior flexibility, chemical resistance, and durability compared to traditional epoxy coatings. These properties make HDPE liners particularly suited to the environmental conditions of Southern California.

Environmental and Seismic Challenges in Southern California

Southern California has a mix of environmental and seismic conditions that can damage concrete structures. The region often sees hot, dry summers followed by rainy winters. These extreme temperature changes cause concrete to expand and contract, leading to cracks over time.

Coastal areas face additional challenges from salt in the air. Salt can seep into the concrete and reach the steel reinforcements inside. This salt exposure speeds up corrosion, weakening the concrete and reducing the structure’s lifespan. Buildings, bridges, and roads near the coast are at higher risk of damage due to this salty environment.

The region is also prone to earthquakes. Southern California sits on several active fault lines, making seismic activity a constant threat. Earthquakes, even minor ones, can make existing cracks worse or create new ones. This constant movement further stresses concrete structures, increasing the need for protective measures that can withstand these conditions.

To sum up, the environmental and seismic challenges in Southern California make protecting concrete structures essential. Adapting to these unique conditions ensures the long-lasting safety and durability of concrete infrastructure.

Key Differences Between HDPE Liners and Epoxy Coatings

When protecting concrete, both HDPE liners and epoxy coatings are popular options. However, some key differences make HDPE liners a better choice for Southern California.

● Flexibility: HDPE liners are highly flexible. They move along with concrete as it expands and contracts, preventing cracks and splits. On the other hand, epoxy coatings are rigid and can crack under the same conditions.

● Chemical Resistance: HDPE liners provide excellent resistance to a wide range of chemicals, especially salts from coastal air. This resistance helps prevent corrosion. Epoxy coatings also offer chemical resistance but tend to degrade faster in extreme conditions.

● Durability: HDPE liners boast impressive durability. They withstand environmental stressors like temperature swings and chemical exposure without deteriorating quickly. Epoxy coatings, although strong, show signs of wear and tear under similar conditions more rapidly.

● Ease of Installation: Installing HDPE liners is easier and quicker. They can be pre- fabricated to fit specific shapes, reducing labour time and costs. Epoxy coatings require meticulous surface preparation and long curing times, making the installation process more demanding.

● Maintenance: HDPE liners require minimal maintenance once installed. They remain effective for extended periods, reducing the need for frequent repairs. Epoxy coatings, meanwhile, need more regular maintenance to stay in good condition. HDPE liners outperform epoxy coatings in several crucial areas, making them the superior choice for concrete protection in Southern California.

Long-Term Benefits of HDPE Liners for Concrete Protection

Choosing HDPE liners for concrete protection offers several long-term benefits. The flexibility of HDPE liners ensures that they accommodate the natural movement of concrete, reducing the risk of cracks and damage over time. This flexibility is vital in areas like Southern California, where temperature changes and seismic activity are common. HDPE liners also provide superior chemical resistance. They protect concrete from damaging substances like salt, chemicals, and other corrosive elements. This protection extends the lifespan of the concrete, saving on repair and replacement costs in the long run. Unlike epoxy coatings, which may degrade faster under harsh conditions, HDPE liners maintain their integrity for longer periods.

Durability is another significant advantage. HDPE liners can withstand various environmental stressors without deteriorating quickly. They offer a reliable solution that ensures concrete structures remain strong and intact over time. Additionally, HDPE liners require less maintenance, which further reduces long-term costs. Lower maintenance needs mean fewer interruptions and cost savings for property owners and businesses. Overall, investing in HDPE liners for concrete protection provides a durable, flexible, and low- maintenance solution that withstands the unique challenges of Southern California, making it a more economical choice in the long run.

Practical Applications and Real-World Examples of HDPE Liners

HDPE liners are used in a variety of practical applications across Southern California. Here are some key areas where HDPE liners prove to be effective:

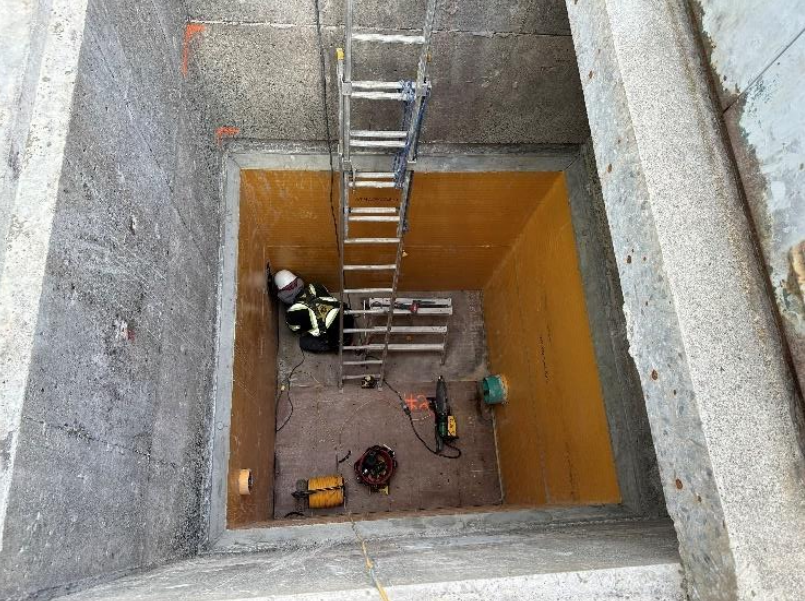

● Water and Wastewater Treatment Plants: HDPE liners are ideal for lining tanks and containment areas, preventing leaks and resisting harsh chemicals used in the treatment process.

● Secondary Containment Systems: Industrial settings benefit from HDPE liners as they add an extra layer of protection for secondary containment systems, containing spills from tanks holding chemicals or wastewater.

● Landfills: HDPE liners are commonly used in landfills to line cells and cover systems, preventing harmful leachate from contaminating the soil and groundwater.

● Reservoirs and Canals: For water storage and management systems, HDPE liners prevent water loss and protect concrete from chemical exposure and environmental stressors.

● Agricultural Ponds: HDPE liners are effective in agricultural ponds for holding irrigation water or wastewater. They help maintain water quality and prevent seepage.

● Pools: Commercial and residential pools also benefit from HDPE liners, providing a durable, leak-proof barrier that extends the pool’s life.

These applications show the versatility and effectiveness of HDPE liners in protecting concrete structures across different settings. Their ability to meet the unique challenges of Southern California makes them a preferred choice for various uses.

Which Is Better for Southern California Concrete: HDPE Liners or Epoxy?

Southern California’s environmental and seismic conditions require robust solutions for concrete protection. HDPE liners offer a superior alternative to traditional epoxy coatings, providing the necessary flexibility, chemical resistance, and durability to withstand these challenges. Their long-term benefits, including reduced maintenance and increased lifespan of concrete structures, make them a cost-effective choice.

If you’re looking to protect your concrete structures from Southern California’s unique challenges, consider the benefits of HDPE liners. For more information on how our wide range of concrete protective liners can offer the best protection for your needs, contact Engineered Containment today and ensure your structures remain strong and durable for years to come.

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!