HDPE Liners vs. Epoxy for California Concrete Protection

HDPE Liners vs. Epoxy for California Concrete Protection

California’s diverse climate poses significant challenges for concrete structures. With temperatures soaring in the summer and dipping in the winter, concrete expands and contracts, leading to cracks and weaknesses over time. Add to this the impact of seismic activity and the corrosive effects of coastal salt air, and it becomes clear that choosing the right protective coating is crucial to maintaining the integrity and longevity of concrete structures in the region.

Traditionally, epoxy coatings have been a go-to solution for concrete protection. Epoxy offers a hard, durable surface that can shield concrete from some environmental factors. However, epoxy also has its limitations, especially under the demanding conditions typical of California. Cracking, limited chemical resistance, and the need for meticulous surface preparation can make epoxy less effective over time.

This is where HDPE (High-Density Polyethylene) liners come into play. HDPE liners provide a flexible, durable alternative that can withstand the harsh conditions that cause epoxy coatings to fail.

California's Climate and the Impact on Concrete

California’s climate is tough on concrete. The state experiences big temperature swings between summer and winter. In the summertime, temperatures can get extremely high. This heat causes concrete to expand. When winter rolls around and temperatures drop, the concrete contracts. This constant cycle of expanding and contracting causes cracks to form. Over time, these cracks can grow, leading to significant structural damage.

Another major problem is earthquakes. California sits on several fault lines, making it prone to seismic activity. Even minor earthquakes can vibrate and shake concrete structures, causing cracks and breaks. In stronger earthquakes, the damage can be severe, compromising the safety of buildings, bridges, and other structures.

Coastal areas add another layer of complexity. The air near the ocean contains salt, which is very corrosive. Salt can penetrate concrete and cause rust on any metal reinforcements inside. This rust weakens the concrete from the inside out, leading to faster deterioration. For concrete structures in coastal regions, the combination of salt air and temperature changes can be especially damaging.

The Limitations of Epoxy Coatings

Epoxy coatings have been used to protect concrete for many years. They create a hard, durable surface that can shield concrete from some damage. However, epoxy is not perfect, especially in a challenging environment like California.

First, epoxy is rigid. It does not flex with the concrete as it expands and contracts. This lack of flexibility means that epoxy coatings can crack and chip, especially when subjected to temperature changes and seismic activity.

Second, epoxy's chemical resistance is limited. While it can protect against some chemicals and moisture, it is not as effective in harsh environments. Salt, for instance, can still find its way through, slowly breaking down the epoxy and damaging the concrete beneath.

Installation and maintenance of epoxy coatings also present challenges. The surface must be meticulously prepared before applying epoxy, requiring a clean, dry, and dust-free environment. Curing times can delay project completion, and if the application is not done correctly, the coating may not adhere properly. Over time, maintaining epoxy can be costly and labour-intensive, as it may require frequent repairs or reapplications.

These limitations make epoxy coatings less suitable for protecting concrete structures in a demanding environment like California. This is where HDPE liners offer a significant advantage, providing better flexibility, chemical resistance, and easier installation and maintenance.

The Advantages of Engineered Containment’s HDPE Concrete Protective Liners

HDPE liners provide several key benefits for concrete protection. One of the main advantages is their flexibility. Unlike rigid epoxy coatings, HDPE liners can move with the concrete as it expands and contracts. This flexibility helps prevent cracks and keeps the concrete intact over time, especially in regions with temperature fluctuations like California.

Another significant benefit is the chemical resistance of HDPE liners. They form a strong barrier against chemicals, moisture, and salt, which can deteriorate concrete. This is crucial for concrete structures near the coast, where salt air can cause serious damage. By using HDPE liners, the concrete is shielded from these harmful elements, ensuring long-term durability.

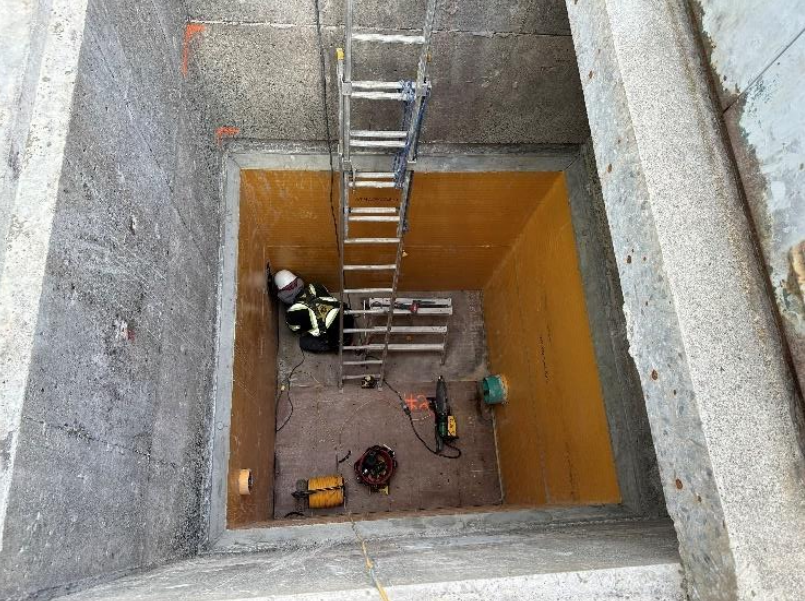

Installation of HDPE liners is also more straightforward compared to epoxy coatings. HDPE liners are prefabricated to fit specific shapes and sizes, making them easier to install. They do not require as meticulous surface preparation and cure almost immediately, allowing projects to be completed faster. Once installed, HDPE liners require minimal maintenance, reducing long-term costs and effort.

How to Choose the Best Concrete Protection for Your Needs

When choosing the best concrete protection, consider several factors. Understanding the specific environmental challenges your structure faces is crucial. In California, this often means accounting for temperature changes, seismic activity, and coastal salt air. HDPE liners are particularly suited to these conditions due to their flexibility and chemical resistance.

Evaluate the long-term costs and maintenance needs. While epoxy coatings may seem cheaper initially, they often require more frequent maintenance and repairs. HDPE liners, with their longer lifespan and lower maintenance requirements, can be more cost-effective over time. Consider the ease of installation too. HDPE liners typically offer simpler and quicker installation compared to epoxy coatings, saving you both time and money.

Lastly, think about the overall protection your concrete needs. HDPE liners provide a comprehensive shield against a wide range of damaging elements. They are especially beneficial for structures exposed to harsh environmental conditions. By focusing on these factors, you can make an informed decision and choose the best protection for your concrete structures, ensuring their durability and safety for years to come.

Why Concrete Protective Liner?

Protecting concrete structures in California involves dealing with temperature fluctuations, seismic activity, and coastal salt air. Epoxy coatings, while traditional, have significant limitations, such as rigidity, limited chemical resistance, and challenging installation processes. HDPE liners, on the other hand, offer superior flexibility, robust chemical resistance, and easier installation and maintenance, making them better suited for the environmental challenges in California.

HDPE liners provide a durable, long-lasting solution for concrete protection. Their flexibility helps accommodate the natural movements of concrete, reducing the risk of cracks. They also create a strong barrier against corrosive substances, ensuring that the concrete remains intact and strong over time. Furthermore, the ease of installation and minimal maintenance requirements make HDPE liners a cost-effective choice.

For those looking to safeguard their concrete structures in California, HDPE liners offer reliable and superior protection. At Engineered Containment, we specialize in combining geosynthetics with value engineering to create leak-free containment systems. Contact Engineered Containment today to learn how our concrete protective liners can provide the optimal protection your concrete structures need. Our team is ready to assist you in choosing the best containment system tailored to your specific requirements.

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!