How HDPE Liners Protect Southern California Concrete Better Than Epoxy

HDPE Liners vs. Epoxy: Best for SoCal Concrete

Southern California presents unique challenges for protecting concrete structures. The region is known for its hot, dry summers and cool, wet winters. These extreme temperature changes cause concrete to expand and contract, leading to cracks and other forms of deterioration.

Earthquakes are another significant concern. Southern California is seismically active, with even minor tremors potentially causing or worsening cracks in concrete structures. These cracks can allow water, chemicals, and other harmful substances to penetrate, leading to further damage. Therefore, any protective measure for concrete must be robust enough to withstand environmental stress and seismic activity.

With that in mind, we’re here to explore why HDPE liners are superior to epoxy coatings for protecting concrete in Southern California. By understanding the region's environmental and climate challenges, comparing the material properties, and examining the long-term performance and ease of maintenance, we aim to demonstrate why HDPE liners are the best choice for concrete protection.

Environmental and Climate Challenges in Southern California

Southern California faces unique environmental and climate challenges that put concrete structures at high risk. The region experiences significant temperature fluctuations, with hot, dry summers and mild, wet winters. This constant change forces concrete to expand and contract, leading to cracks and weakening over time. Smaller cracks seem harmless but allow water and chemicals to seep into the concrete, causing further damage and reducing its lifespan.

Additionally, coastal areas in Southern California endure the adverse effects of salty ocean air. Salt accelerates the corrosion process by penetrating the concrete and reaching the steel reinforcements inside. Corroded steel weakens the structural integrity, making buildings, roads, and other infrastructures unsafe and expensive to repair.

Earthquake activity is another critical factor. Southern California sits on several fault lines, making the region prone to frequent seismic activities. Even minor earthquakes can create or worsen cracks in concrete structures, making them more vulnerable to environmental and chemical damage.

Given these challenges, it becomes essential to choose a protective solution like HDPE liners to enhance the durability and safety of concrete structures in the region.

Material Properties: HDPE Liners vs. Epoxy Coatings

When comparing HDPE liners to traditional epoxy coatings, several key differences highlight why HDPE liners are the superior choice for concrete protection in Southern California.

Flexibility: HDPE liners offer remarkable flexibility. They move with the concrete as it expands and contracts due to temperature changes, preventing cracks and splits. In contrast, epoxy coatings are rigid and prone to cracking when the concrete shifts.

Chemical Resistance: HDPE liners excel in resisting a wide range of harsh chemicals, including salts from ocean air and various industrial chemicals. This resistance protects the concrete from corrosion. Although epoxy coatings provide some chemical resistance, they degrade faster when exposed to extreme conditions and harsh substances.

Durability: HDPE liners boast impressive durability. They withstand harsh environmental conditions, including significant temperature swings and chemical exposure, without deteriorating quickly. Epoxy coatings, while strong, often show signs of wear and tear faster under similar conditions.

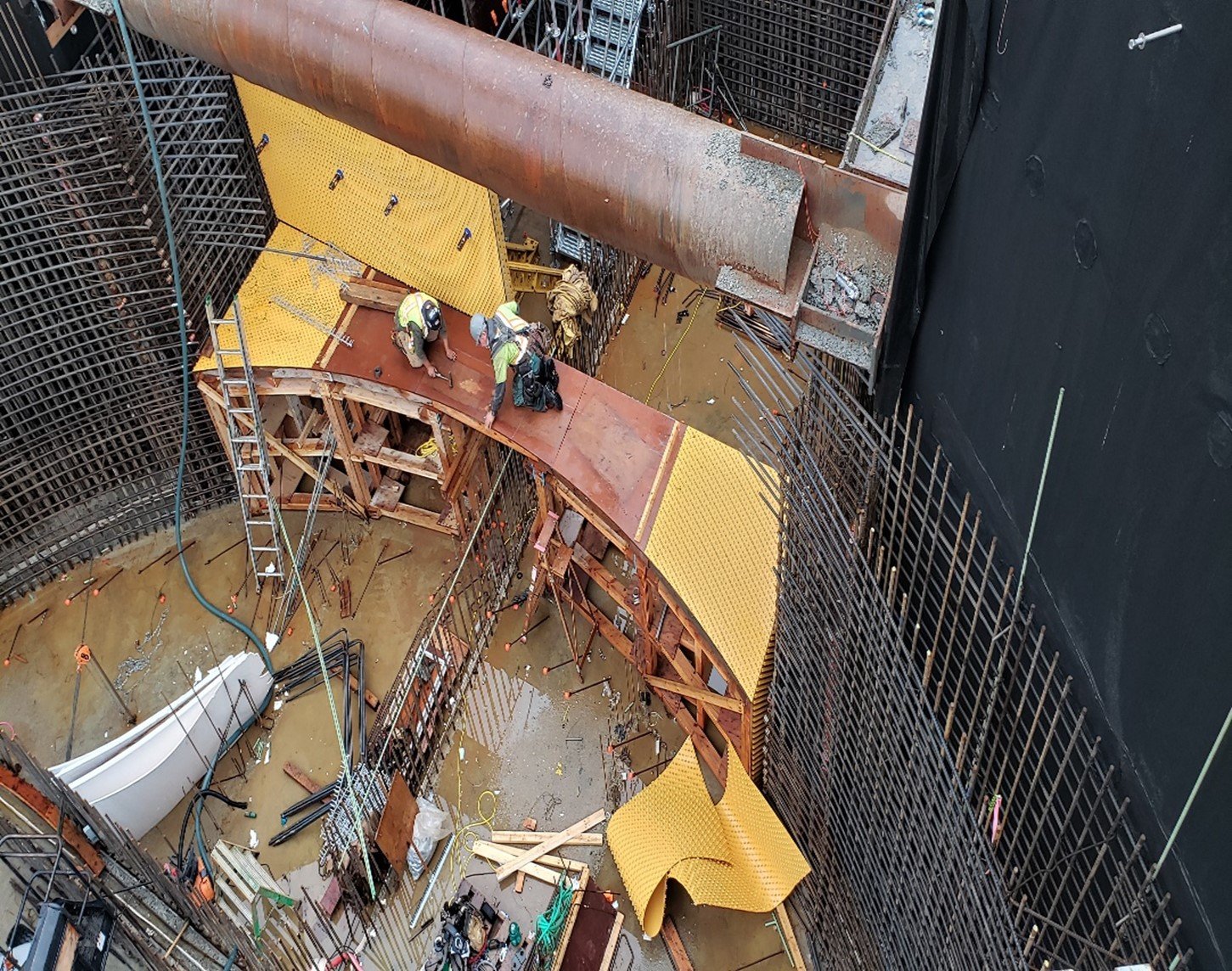

Ease of Installation: Installing HDPE liners is quicker and simpler. HDPE liners can be pre-fabricated to specific shapes and sizes, reducing labour time and costs. In contrast, installing epoxy coatings requires meticulous surface preparation and longer curing, making the installation process more demanding.

Low Maintenance: Once installed, HDPE liners need minimal maintenance. They continue to perform effectively over long periods, reducing both the frequency and cost of repairs. Epoxy coatings, on the other hand, typically require more frequent maintenance to keep them in good condition.

These material properties—flexibility, chemical resistance, durability, ease of installation, and low maintenance—make HDPE liners an unbeatable choice for concrete protection in Southern California.

Long-Term Performance and Durability

HDPE liners are well-known for their long-term performance and durability. Their ability to endure harsh conditions makes them an excellent choice for concrete protection in Southern California. The flexibility of HDPE liners allows them to adapt to temperature changes without cracking, which is crucial for the hot summers and mild winters experienced in this region.

Chemical Resistance: HDPE liners resist degradation from a variety of chemicals, including salts, acids, and industrial solvents. This resistance helps maintain the integrity of concrete structures over long periods, even in environments laden with harmful chemicals.

UV Resistance: Over time, exposure to sunlight can cause many materials to break down or weaken. HDPE liners are designed to resist UV radiation, which further extends their lifespan and reduces the need for frequent replacements.

Seamless Protection: HDPE liners can be welded together to form a seamless barrier. This continuous protection ensures that there are no weak points where moisture or chemicals can penetrate. A seamless barrier is particularly beneficial in areas prone to earthquakes, where any weak spot could quickly become a larger crack due to seismic activity.

Low Maintenance: Since HDPE liners maintain their performance over time, they require less frequent maintenance and repair. This long-lasting durability not only saves on maintenance costs but also minimizes downtime for concrete structures.

Overall, the long-term performance and durability of HDPE liners make them a reliable option for ensuring the longevity of concrete structures across Southern California.

Installation and Maintenance Benefits of HDPE Liners

HDPE liners offer clear advantages when it comes to installation and maintenance. These benefits contribute to their popularity as an efficient solution for concrete protection.

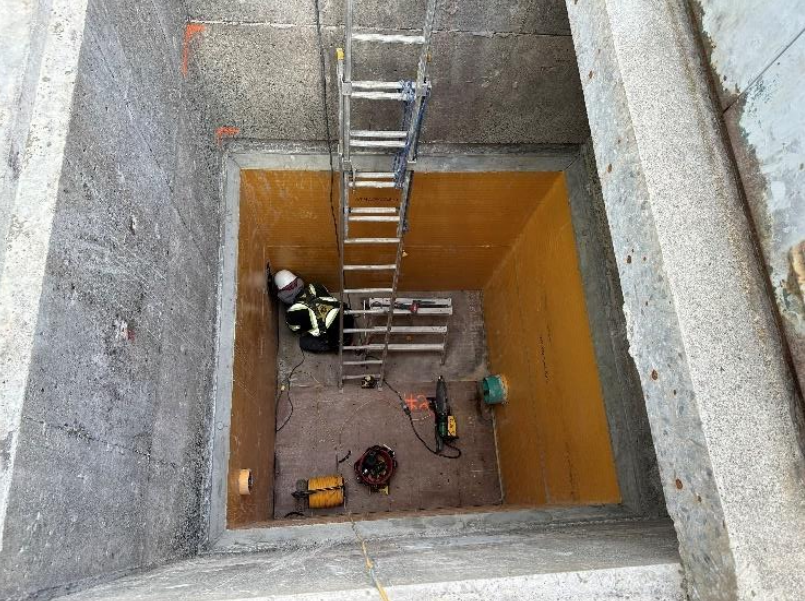

Ease of Installation: HDPE liners are straightforward to install. They can be pre-fabricated to fit specific dimensions and shapes, reducing the need for on-site adjustments. This pre-fabrication saves time and labour costs, allowing for faster project completion. The welding process used to join HDPE liners is also simpler and quicker compared to the application of epoxy coatings.

Less Surface Preparation: Unlike epoxy coatings, which require extensive surface preparation including cleaning, drying, and sometimes priming, HDPE liners need less prep work. This lower demand for surface preparation makes HDPE liners a more convenient and cost-effective choice.

Reduced Downtime: Faster installation means less downtime for your structures. Whether you’re working on a new project or retrofitting an existing concrete structure, the rapid installation process minimises the time the area is out of service.

Minimal Maintenance: One of the standout benefits of HDPE liners is their minimal maintenance requirement. Once installed, HDPE liners stay effective for years, withstanding environmental stresses and chemical exposure without significant wear. This reduces the frequency and costof maintenance, allowing for a more predictable maintenance schedule.

Easy Repairs: In the rare case that repairs are needed, HDPE liners are easier to patch than epoxy coatings. Small sections can be welded seamlessly, maintaining the integrity and protection of the original liner.

These installation and maintenance benefits illustrate why HDPE liners are an ideal choice for protecting concrete structures in Southern California. They offer a practical and cost-effective solution that ensures long-lasting protection with minimal upkeep.

Protecting Southern California Concrete: Why HDPE Liners Are Better Than Epoxy

Concrete structures in Southern California face unique challenges due to the region’s climate, seismic activity, and environmental conditions. Selecting the right protective measure is critical to maintaining their structural integrity and longevity. HDPE liners offer several advantages over traditional epoxy coatings, making them the superior choice for concrete protection.

The flexibility, chemical resistance, and durability of HDPE liners ensure they can withstand the harsh conditions of Southern California. Their ease of installation and low maintenance requirements further contribute to their practicality and cost-effectiveness. HDPE liners provide a seamless and reliable barrier against environmental and chemical threats, helping to extend the lifespan of concrete structures.

For anyone looking to protect their concrete investments, HDPE liners represent the best option. At Engineered Containment, we specialize in providing high-quality concrete protective liner solutions tailored to meet the specific needs of your project. Reach out to us today to learn how we can help safeguard your concrete structures for years to come!

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!