How HDPE Liners Save California Concrete from Damage

Learn how HDPE liners save California concrete from damage. Discover their benefits over epoxy coatings and long-term advantages.

Concrete is a key building material in California, but it faces many challenges from the environment. With its diverse climate, the state sees extreme temperatures, sudden temperature changes, and even earthquakes. These factors can cause significant damage to concrete structures, leading to cracks, erosion, and costly repairs. Protecting concrete in such conditions is essential for maintaining safety and longevity.

Traditional methods like epoxy coatings have been used to protect concrete, but they come with several limitations. Epoxy can crack easily under stress and doesn't always provide the best barrier against chemicals and moisture. This is where HDPE (High-Density Polyethylene) liners come into play. These liners offer a more robust solution for keeping concrete safe from harm.

HDPE liners are designed to handle the unique environmental conditions of California. They are flexible, durable, and provide excellent resistance against chemicals and other corrosive materials.

Understanding Concrete Damage in California

California’s environment is harsh on concrete structures. One major factor is the state’s temperature fluctuations. During summer, temperatures can soar, causing concrete to expand. In the cooler winter months, it contracts. This constant expansion and contraction lead to cracks and weakening over time.

Earthquakes are another significant threat. California is located on several fault lines, making it prone to seismic activity. Even minor tremors can cause damage to concrete structures, resulting in cracks and breaks that compromise their integrity. In the event of a major earthquake, the damage can be severe, necessitating extensive repairs.

Coastal areas present additional challenges. The salt from ocean air is corrosive and can penetrate concrete, leading to erosion and rusting of any internal steel reinforcements. This corrosion weakens the structure from the inside, making it more susceptible to cracks and other forms of damage. HDPE liners are particularly effective in addressing these challenges, as they offer superior protection against such environmental risks.

Why HDPE Liners Are the Superior Choice

HDPE liners excel where traditional methods, such as epoxy coatings, fall short. One key advantage is their flexibility. HDPE liners can move with the concrete as it expands and contracts, which helps prevent cracks from forming. This flexibility is crucial for maintaining the integrity of the concrete in California’s varying climate conditions.

Chemical resistance is another strong point of HDPE liners. These liners create a robust barrier against corrosive substances like saltwater and chemicals. This protection is especially important in coastal areas, where salt can cause significant damage to concrete. By preventing harmful substances from reaching the concrete, HDPE liners help maintain its strength and durability.

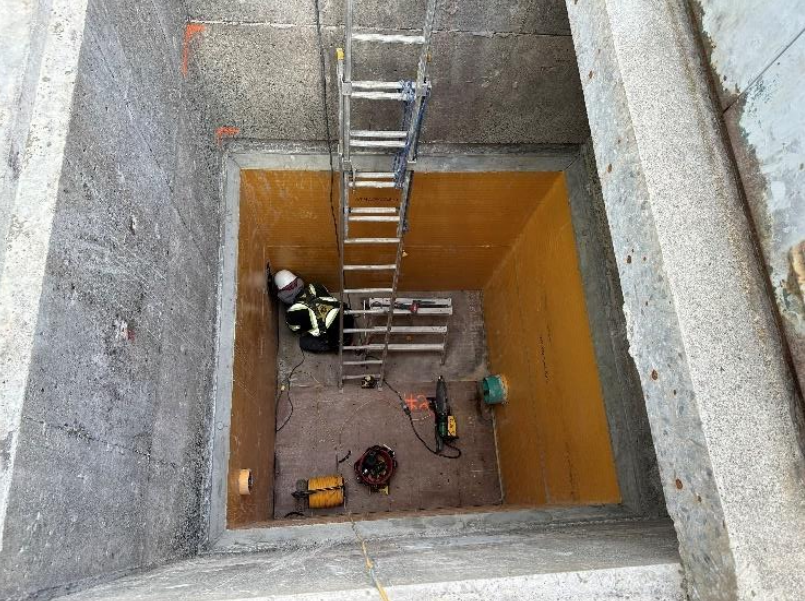

Installation and maintenance of HDPE liners are also simpler and more cost-effective compared to epoxy coatings. HDPE liners are often pre-fabricated to fit specific shapes, making installation easier. Once installed, they require minimal maintenance, which reduces long-term costs and effort. Due to these advantages, HDPE liners provide an effective and reliable solution for protecting concrete structures in California.

Comparing HDPE Liners and Epoxy Coatings

When choosing between HDPE liners and epoxy coatings for concrete protection, it’s essential to compare their characteristics and performance. Flexibility is a major factor where HDPE liners shine. They can move with the concrete, accommodating expansion and contraction without cracking. Epoxy coatings, however, are rigid and more likely to crack under stress.

Chemical resistance is another crucial point of comparison. HDPE liners provide a robust barrier against chemicals, moisture, and salt, preventing these substances from causing damage. Epoxy coatings offer some chemical resistance, but they can break down over time, especially under constant exposure to harsh environments. This degradation leaves the concrete exposed and vulnerable.

In terms of installation, HDPE liners are often easier and quicker to install compared to epoxy coatings. HDPE liners are pre-fabricated to fit specific shapes, reducing the time and effort needed for installation. Epoxy coatings require a clean, dry surface and can take a long time to cure, which can delay projects. Maintenance is also simpler with HDPE liners, as they require less frequent repairs and upkeep compared to epoxy coatings. Overall, HDPE liners offer superior performance, making them the better choice for long-term concrete protection.

Long-Term Benefits of HDPE Liners for Concrete Protection

The long-term benefits of using HDPE liners for concrete protection are substantial. One of the main advantages is their durability. HDPE liners are designed to withstand extreme weather, temperature fluctuations, and seismic activity. This durability means they last longer than other protective coatings, such as epoxy, resulting in fewer repairs and lower costs over time.

Another significant benefit is their low maintenance requirements. Once installed, HDPE liners need minimal upkeep, freeing you from frequent and costly maintenance schedules. This characteristic makes them a cost-effective solution in the long run, providing consistent protection without ongoing expenses.

HDPE liners also contribute to environmental sustainability by extending the lifespan of concrete structures. By preventing damage and reducing the need for repairs, they minimize waste and resource consumption. This long-term environmental benefit aligns with modern sustainability goals, making HDPE liners a smart choice for those who consider the impact on future generations. Choosing HDPE liners ensures that concrete structures remain strong, safe, and operational for many years.

Why Concrete Protective Liner?

Protecting concrete structures in California is crucial due to the state’s challenging environmental conditions. HDPE liners offer the best solution for this protection, outperforming traditional epoxy coatings in flexibility, chemical resistance, and ease of installation. They adapt to the natural movement of concrete, provide an excellent barrier against harmful substances, and require less maintenance, making them a practical and cost-effective choice.

Investing in HDPE liners means choosing long-term durability and sustainability. Their ability to withstand California’s climate, coupled with minimal maintenance needs, ensures that concrete structures remain intact and reliable over time. This investment protects your assets and aligns with environmental sustainability efforts by reducing waste and resource consumption.

Ready to protect your concrete structures with the best solution available? Contact Engineered Containment today to learn more about how our HDPE liners can provide the durable, long-lasting protection your structures need. Our team is here to help you choose the right containment system tailored to your specific needs. Reach out to us now for expert advice and top-quality solutions.

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!