Miami Concrete Protection: HDPE Liners vs Epoxy

Concrete is a critical material in Miami's infrastructure, enduring everything from harsh weather conditions to saltwater exposure. Protecting these concrete structures is essential to ensure their longevity and performance. Two popular methods for concrete protection are HDPE liners and epoxy coatings. Each has its strengths and weaknesses, making it important to understand which option is best suited to meet Miami's unique environmental challenges.

HDPE, or High-Density Polyethylene, liners have gained popularity due to their flexibility and durability. These liners create a seamless, impermeable barrier that guards against water and chemical damage. They are particularly advantageous in wet and humid conditions, as they can expand and contract without cracking, maintaining their protective qualities over time.

Epoxy coatings, on the other hand, are known for their hard, durable surface that adheres strongly to concrete. They are commonly used in industrial settings where chemical resistance is crucial. However, their rigidity can be a drawback in environments like Miami, where high humidity and temperature fluctuations can lead to cracking and delamination.

By examining their material properties, performance in wet conditions, resistance to chemical and physical damage, and economic considerations, you'll be better equipped to choose the most effective solution for your concrete protection needs.

Material Properties and Application Techniques

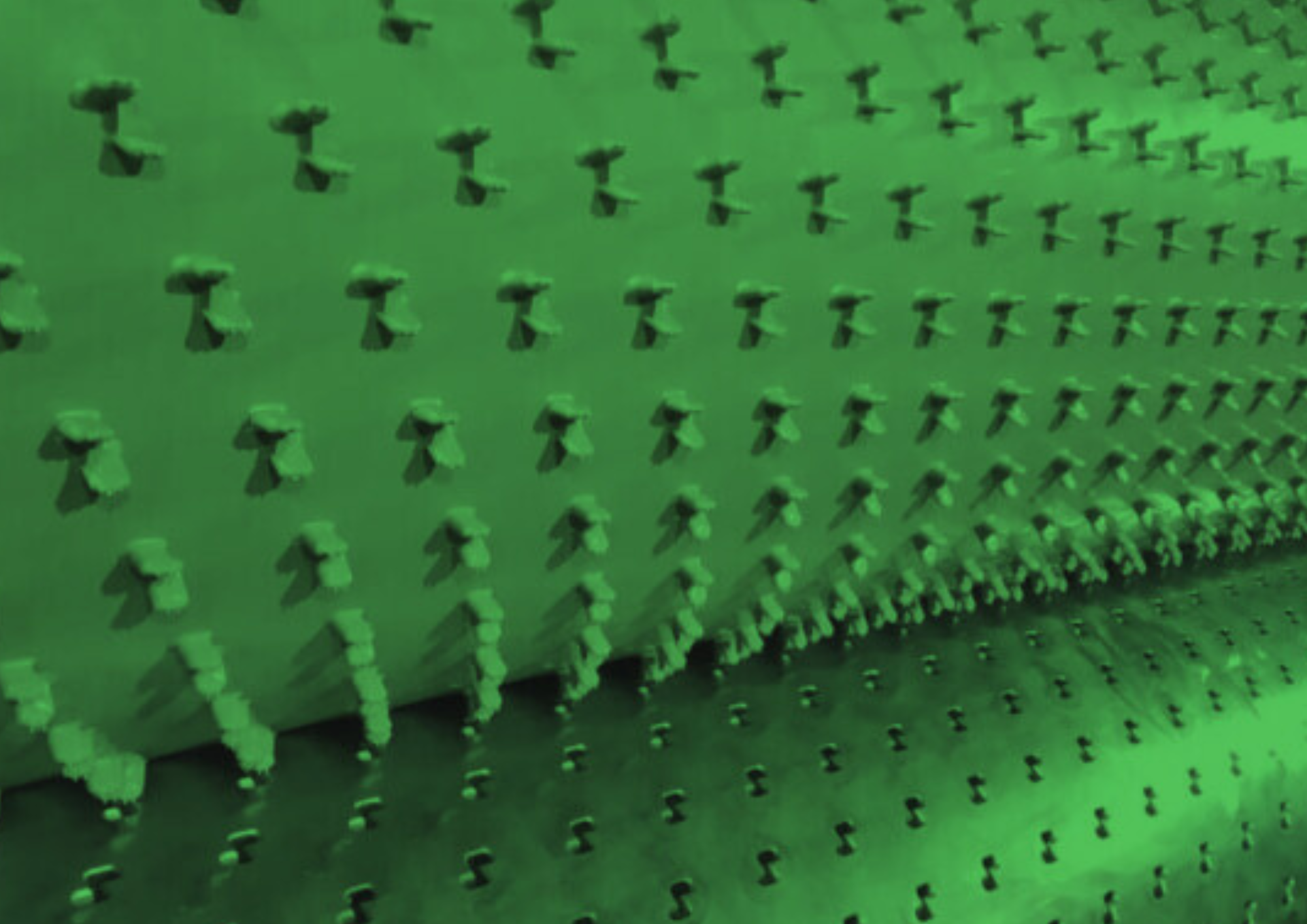

Understanding the material properties and application techniques of HDPE liners and epoxy coatings is crucial for choosing the right protection for concrete structures. HDPE liners are made from high-density polyethylene, a plastic known for its strength, flexibility, and chemical resistance. These liners are usually prefabricated and then installed onto the concrete surface. This process involves welding the seams together to create a seamless and waterproof barrier. The flexibility of HDPE liners allows them to conform to the shape of the concrete structure, ensuring a tight fit and effective protection.

Epoxy coatings, however, are composed of a resin and a hardener that, when mixed, form a rigid, durable surface on the concrete. The application of epoxy coatings usually involves surface preparation, such as cleaning and etching the concrete to ensure proper adhesion. After this, the epoxy mixture is applied using rollers or sprayers. While epoxy coatings provide a tough protective layer, their rigidity means they can be prone to cracking if the underlying concrete moves or shifts.

The main advantage of HDPE liners is their ability to maintain integrity even when the concrete undergoes thermal expansion or contraction. The flexibility of HDPE makes it less likely to crack under pressure. Meanwhile, the rigid nature of epoxy coatings, though durable, can be their downfall, as any movement in the concrete can lead to cracks, compromising the coating's protective qualities.

Performance in Wet and Humid Conditions

Miami's wet and humid climate poses a significant challenge for concrete protection. HDPE liners are well-suited for these conditions because of their excellent moisture resistance. High-density polyethylene is impermeable to water, creating an effective barrier that prevents moisture from penetrating the concrete. This helps to prevent common issues like spalling, mould growth, and corrosion of steel reinforcements within the concrete. HDPE liners also maintain their properties over a wide range of temperatures, making them reliable even during Miami's hot and humid summers.

Epoxy coatings, while still providing some level of moisture resistance, cannot match the performance of HDPE liners in consistently wet conditions. The hard, rigid layer of epoxy can become compromised if any damage or cracks occur, which allows water to seep through and damage the concrete. Over time, the presence of moisture can worsen these cracks, leading to extensive and costly repairs.

The adaptability of HDPE liners to expand and contract with temperature changes also gives them an edge in Miami's climate. This flexibility ensures that the protective barrier remains intact, even when the concrete undergoes thermal stress. In contrast, epoxy coatings lack this flexibility, making them more prone to cracking and failure in a humid and wet environment. Therefore, HDPE liners offer superior performance in protecting concrete structures in Miami's challenging climatic conditions.

Resistance to Chemical and Physical Damage

Concrete structures in Miami face not only environmental challenges but also exposure to chemicals and physical wear and tear. HDPE liners are robust against chemical attack, thanks to their inherent resistance to a wide range of acids, bases, and salts. This makes them particularly effective in industrial or coastal settings where chemical exposure is high. The chemical resistance of HDPE ensures that the protective barrier remains intact, preventing any deterioration of the concrete.

In terms of physical damage, HDPE liners also hold an advantage. Their flexibility means they can absorb impacts and stress without cracking or breaking. This is crucial in areas that experience frequent heavy loads or mechanical wear. The seamless nature of HDPE liners further improves their resistance to physical damage, as there are no weak points that could lead to failure.

Epoxy coatings, while strong and durable, are more susceptible to chemical and physical damage in certain conditions. Chemicals can eventually penetrate and weaken the epoxy layer, especially if the surface is already compromised by cracks. Additionally, the rigidity of epoxy makes it more prone to cracking under physical stress or impacts. This can lead to costly repairs and reduced effectiveness over time.

Economic Considerations: Installation and Long-Term Maintenance

When it comes to cost, both initial installation and long-term maintenance are important factors to consider. Installing HDPE liners involves a higher initial cost due to the complexity and material requirements. However, this investment is often offset by the low maintenance costs and long lifespan of the liners. HDPE liners are designed to be durable and resistant to damage, meaning they seldom require extensive repairs or replacements.

Epoxy coatings, on the other hand, tend to have a lower initial installation cost. They are easier to apply and require less material. However, the long-term maintenance costs can be significant. The rigidity of epoxy makes it more prone to cracking and damage over time, necessitating frequent inspections, repairs, or even complete reapplications. These ongoing maintenance requirements can add up, making epoxy coatings potentially more expensive in the long run.

A key advantage of HDPE liners is their longevity. The materials are designed to last for decades, providing continuous protection without the need for frequent intervention. This makes HDPE liners a more cost-effective solution over the lifetime of the concrete structure.

Miami, Florida

United States of America

Choosing the right method for protecting concrete in Miami requires careful consideration of the unique environmental challenges. HDPE liners offer numerous advantages over epoxy coatings, including superior moisture and chemical resistance, flexibility, and reduced long-term maintenance costs. Their ability to withstand the harsh conditions of Miami's climate and their resilience against both chemical and physical damage make HDPE liners the optimal choice for ensuring the longevity and durability of concrete structures.

By understanding the differences between HDPE liners and epoxy coatings, you can make an informed decision to protect your investment effectively. For the best results in concrete protection, consider HDPE liners as a solution that not only meets but exceeds the demands of Miami's tough environment.

Reach out to Engineered Containment to learn more about our HDPE liner solutions and how they can benefit your concrete protection needs. We're here to help you achieve exceptional, leak-free containment systems that stand the test of time. Contact Engineered Containment today to learn how our HDPE liners can help safeguard your concrete structures effectively and efficiently.