The Importance of HDPE Liners for Concrete in Miami

Miami's climate poses significant challenges for concrete structures. The city experiences high humidity, frequent rain, and saltwater exposure due to its coastal location. These environmental factors can cause severe damage to concrete, compromising its integrity and leading to costly repairs. Choosing the right protective method is essential to ensure the longevity and durability of concrete structures in Miami.

Climate Challenges for Concrete in Miami

Miami's climate is tough on concrete structures. High humidity levels are a constant issue, and frequent rain showers can lead to excessive moisture around concrete. This environment accelerates the process of spalling, where the surface layer of the concrete chips or flakes off. Additionally, the city’s coastal location exposes concrete to saltwater, which can penetrate and corrode the steel reinforcements inside the concrete, weakening the overall structure.

Another challenge is Miami’s temperature fluctuations. Concrete naturally expands and contracts with temperature changes. Inconsistent weather patterns, such as hot afternoons followed by cool nights, can lead to the development of cracks. These cracks not only affect the integrity of the concrete but also provide entry points for water and chemicals, further accelerating deterioration.

The combination of humidity, saltwater, and temperature fluctuations makes it essential to use a durable protective system for concrete in Miami. Without proper protection, concrete can suffer significant damage, leading to costly repairs and posing safety risks. This is where HDPE liners come into play, offering a robust solution to these climate challenges.

Advantages of HDPE Liners in Concrete Protection

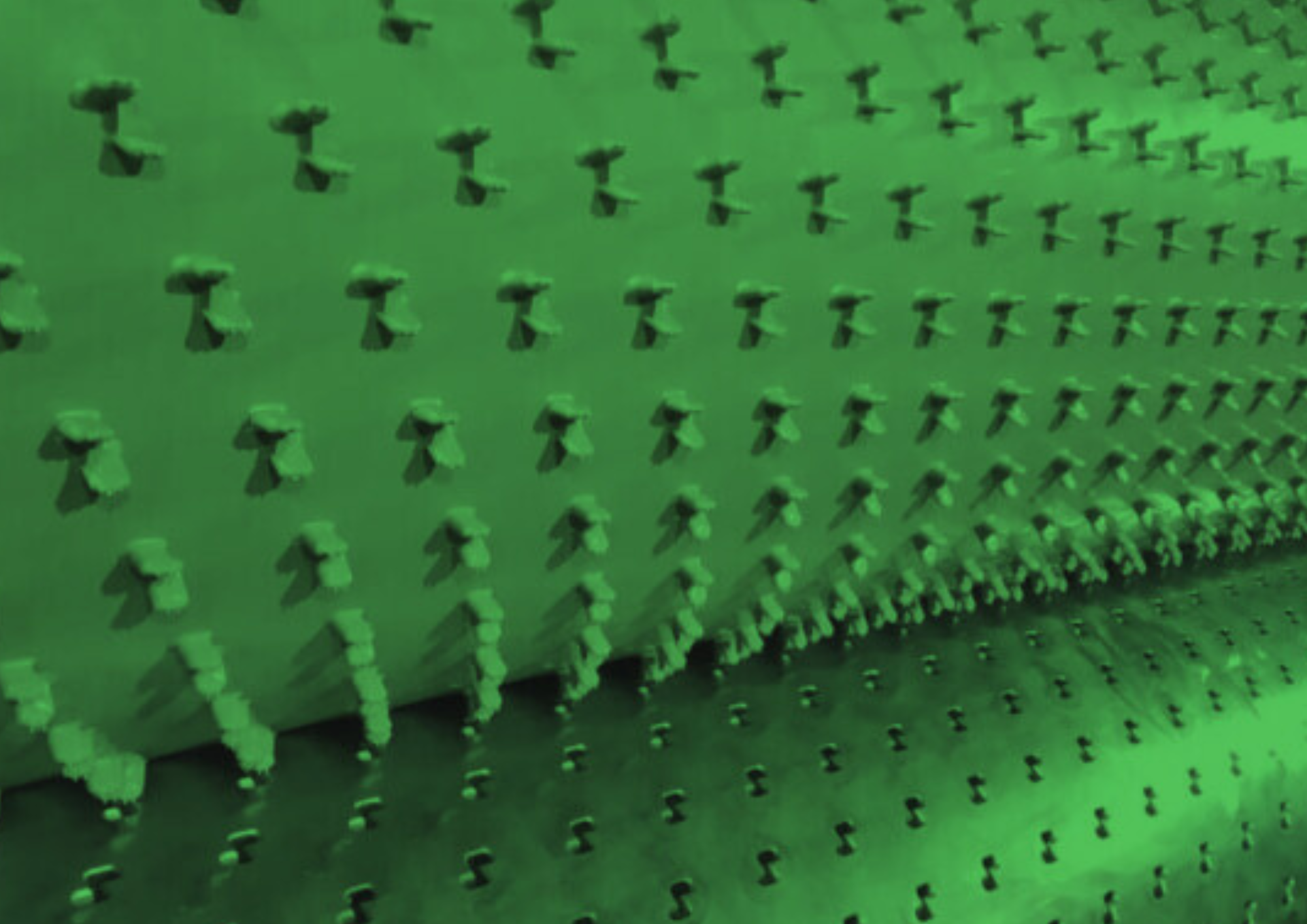

HDPE liners offer several advantages for concrete protection in challenging environments like Miami. One of the key benefits of HDPE liners is their excellent impermeability. High-Density Polyethylene is a durable material that resists water and chemical penetration, creating a strong barrier that safeguards the concrete from moisture and corrosive elements.

Another advantage is the flexibility of HDPE liners. Unlike rigid epoxy coatings, HDPE liners can expand and contract along with the concrete. This adaptability ensures that the protective barrier remains intact, even when the concrete undergoes thermal stress from temperature fluctuations. This flexibility reduces the risk of cracks forming, which can compromise the protective layer and allow harmful substances to infiltrate trunk lines and other essential infrastructure.

HDPE liners are also resistant to a wide range of chemicals, including acids, bases, and salts. This makes them particularly useful in coastal areas like Miami, where saltwater exposure is a constant threat. The chemical resistance helps in preserving the structural integrity of the concrete, preventing deterioration caused by chemical reactions.

Lastly, the installation process of HDPE liners involves welding the seams together to create a seamless, continuous barrier. This seamless structure offers uniform protection across the entire concrete surface, eliminating weak points that might be vulnerable to damage. The high durability and long-lasting nature of HDPE liners make them an ideal choice for protecting concrete structures in Miami’s harsh environment. It is critical to ensure that all of the welding is carried out by certified professionals who have a strong QA/QC program.

Comparing HDPE Liners to Other Protective Methods

When it comes to protecting concrete, several methods are available, each with its own set of pros and cons. One common alternative to HDPE liners is epoxy coatings. While epoxy coatings provide a hard, durable surface that adheres strongly to the concrete, they are not as flexible as HDPE liners. This rigidity can become a disadvantage in environments with substantial temperature changes, like Miami, leading to potential cracks and delamination over time.

Another alternative to HDPE liners is urethane coatings. Urethane coatings offer high resistance to abrasion and chemicals, and they can be flexible to some degree. However, just like epoxy, they require meticulous surface preparation and multiple layers to achieve effective protection. This makes the installation process more cumbersome and time-consuming compared to HDPE liners.

In contrast, HDPE liners provide a comprehensive, long-lasting solution that surpasses the protective capabilities of these alternative methods. Their seamless, flexible, and chemical-resistant properties make HDPE liners the superior choice for concrete protection in challenging environments.

Long-Term Benefits and Cost Savings of HDPE Liners

Investing in HDPE liners for concrete protection offers significant long-term benefits and cost savings. One of the primary advantages is their durability. HDPE liners can withstand harsh environmental conditions without deteriorating. This longevity means fewer repairs and replacements over time, leading to substantial cost savings. This is especially true with underground infrastructure. If a trunk line fails, subsidence (aka sinkholes) become a real threat to land and roadways.

HDPE liners contribute to the structural integrity of concrete, preventing issues like spalling and corrosion of the embedded steel reinforcements. By maintaining the strength and stability of the concrete, HDPE liners help avoid costly structural failures and the extensive repairs associated with them. Additionally, the seamless barrier created by HDPE liners minimizes the risk of leaks, ensuring the protective layer remains effective throughout its lifespan.

Over the long term, the maintenance requirements for HDPE liners are minimal. Unlike other protective methods that may need frequent inspections and touch-ups, HDPE liners provide consistent protection with less ongoing maintenance. This reliability not only saves money but also reduces the effort and resources needed to keep concrete structures in top condition.

The initial investment in HDPE liners pays off through reduced maintenance costs, longer lifespan, and enhanced protection of concrete structures. The long-term benefits and cost savings make HDPE liners a smart and economical choice for protecting concrete in Miami’s challenging environment.

Miami, Florida

United States of America

HDPE liners are essential for preserving the integrity and strength of concrete structures in Miami. They provide a lasting, reliable barrier that outperforms other protective methods. For those looking to safeguard their concrete investments, HDPE liners are the best option.

To learn more about how concrete protective liners can protect your concrete infrastructure projects, contact Engineered Containment today. Our team of experts will help you choose the best solution for your specific needs.